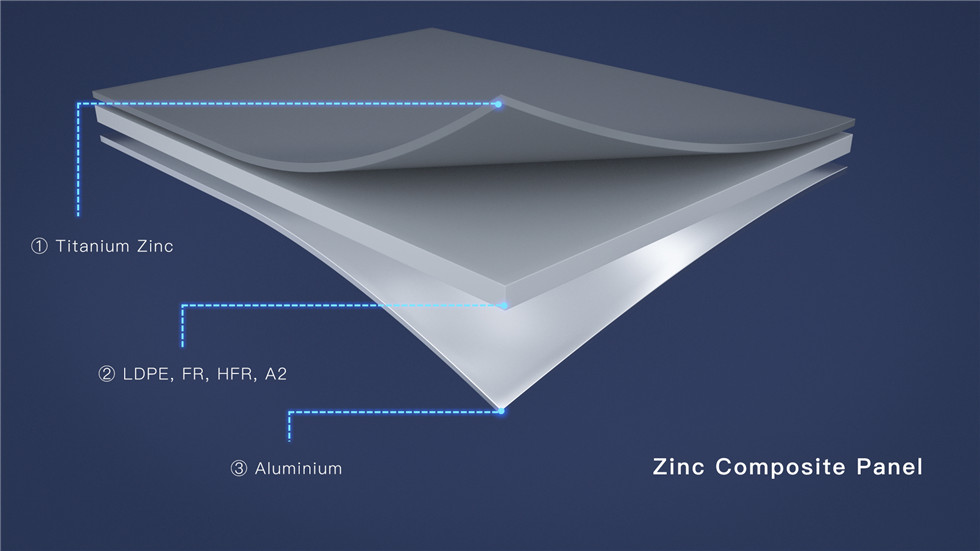

Raw Material

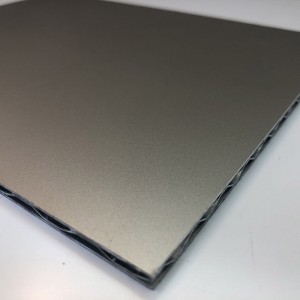

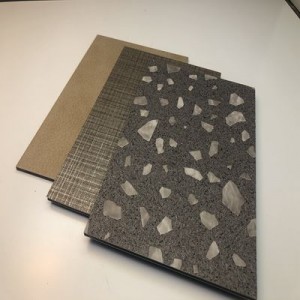

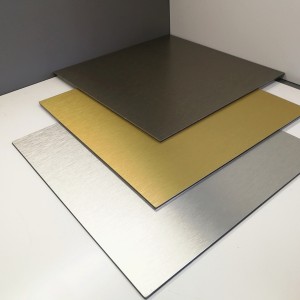

Top Skin: Titanium Zinc

Core Material: LDPE, FR, HFR, A2

Bottom Skin: Aluminum Alloy

Surface Finish: QUARTZ, ANTHRA and PIGMENTO

Specification:

|

Panel Thickness |

4 |

3, 5, 6 |

|

Zinc |

Rheinzink |

VMzinc,Elzinc |

|

Zinc Thickness |

0.5 |

0.7 |

|

Panel Width |

1000mm |

980mm |

|

Panel Length |

2440, 3200 |

Up to 5000 |

Key Advantages:

• Excellent flatness and rigidity

• Panels with large dimensions

• Strong dimensional stability,

• Solutions for complex shapes

• The long life of Zinc

Application

wall cladding, high-grade building wall, hotel and so on

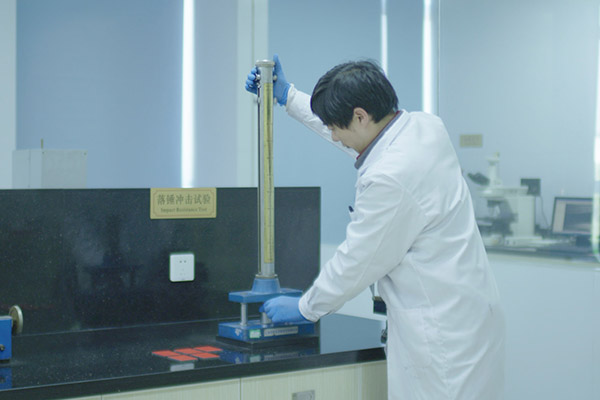

Total Quality Management

Raw Material Test

IPQC,In Process Quality Control

Pre-Shipment Inspection(PSI)

Raw Material Test

IPQC,In Process Quality Control

Pre-Shipment Inspection(PSI)

Write your message here and send it to us